Breathing Air Testing Frequency

In the UK, EN12021 advises that air quality testing and monitoring of samples should be taken and analysed at least every three months or more frequently if there has been a change in, or any concerns relating to, the production process, including if any air compressors have been moved.

Anything that may change the compressed air quality should be tested for health and safety.

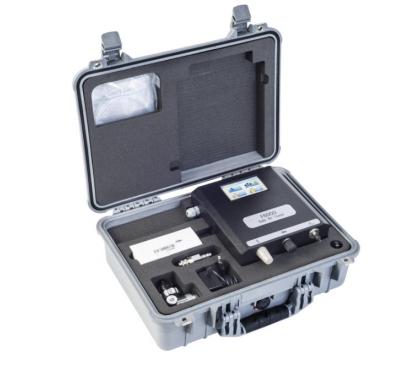

Our equipment confirms the air purity in accordance with the latest BS EN 12021 requirements. You’ll receive the information you need about the quality of your breathing air to ensure you are compliant.

At Air Energy, we offer testing of the full range of organic compounds required to receive the relevant certificates for your workplace to assure compliance with international standard BS EN 12021.

How Much Does Air Quality Testing/Monitoring Cost?

A breathing air quality test will depend on the size of your workplace and other factors. Call us with more information and we will be more than happy to advise.

Why Is Breathing Air Quality Testing Important?

Air quality testing/monitoring is one of the most important things for a few important reasons:

- Protects the health, safety and well-being of your staff and people visiting your premises.

- Ensure your compressor, products and staff are also protected from any volatile organic compounds (VOCs) in the air, detecting toxic or harmful effects.

- Ensures your business is in compliance with UK and International legal standards for breathing quality.

- Ensures your compressed air and work environment has safe levels of oxygen, lubricants, oil, odour, taste, carbon dioxide, carbon monoxide and water content.